SERVICES

EMS: ELECTRONICS

MANUFACTURING SERVICES

High-quality EMS for your electronic projects | Fides Electronics

Fides has over 25 years of experience in the design and production of electronics for clients in the most demanding sectors such as medical, industrial, automotive, and consumer.

For more than 25 years, Fides has provided comprehensive services for full system assembly (Full Box Build) and the manufacturing of electronic products worldwide.

We specialise in sectors with the highest standards, including the medical technology industry, ventilation, professional appliances, and other consumer products such as household appliances.

Our company holds ISO 9001:2015 and ISO 14001 certifications and consistently complies with the requirements of our clients, as well as applicable European and international regulations.

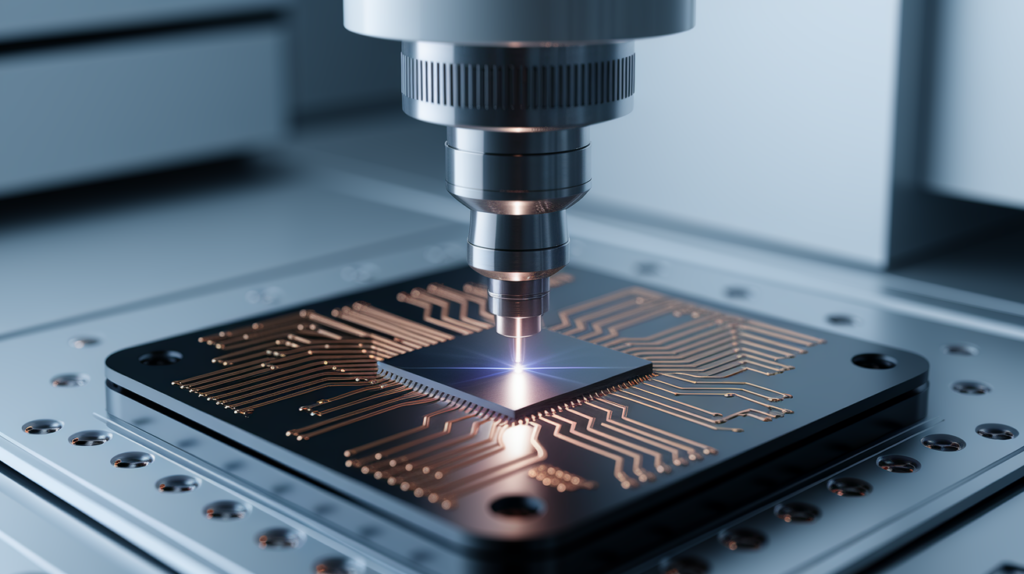

For over two decades, we have been dedicated to the development and manufacturing of electronic products and systems, offering customised turnkey solutions for end products in sectors such as professional appliances, frequency drives, consumer goods, automotive, and the medical industry. Our approach covers everything from conception and design to full production, providing advanced engineering, complete product assembly, and in-house printed circuit board (PCBA) manufacturing. Additionally, we offer fully integrated electromechanical assembly and system integration of the highest quality, including prototyping and ensuring rigorous quality control, among other services.

Cost and quality-oriented design

- Comprehensive evaluation of the Bill of Materials (BOM Open Book)

- Design for Manufacturing (DFM)

- Design for Testability (DFT)

- Design for Assembly (DFA)

- Development of customised, reusable packaging compliant with ESD regulations.

Technological Capabilities:

- Fully customised in-house manufacturing

- Conventional (THT) and surface mount (SMT) assembly in ISO 7 clean room

- Rapid, flexible and efficient line changes and configurations

- Wave soldering

- Selective soldering

- Printed circuit board (PCB) separation

- Integration of mechanical components: includes wiring harness assembly, sensors, motors and enclosures

- Automatic tropicalisation of circuits

- 100% traceability

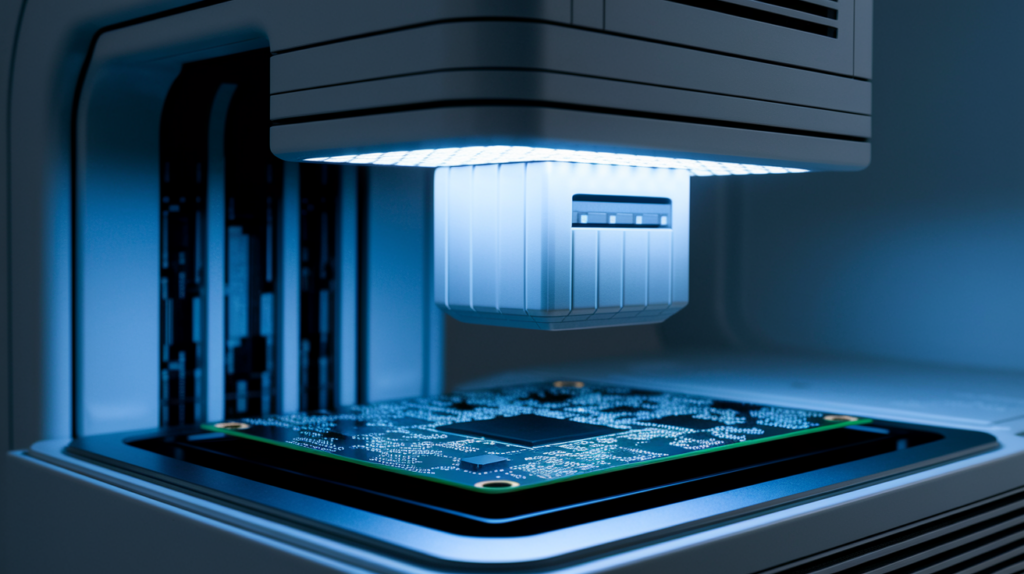

Product Reliability Assurance Testing

- 3D solder paste inspection (SPI)

- Automated 3D optical inspection (AOI)

- 100% in-circuit testing for manufacturing

- Customised functional testing using automated custom equipment

- Electrical safety testing

- Burn-in testing

- Environmental testing (Climatic chamber)

- X-ray inspection and evaluation services

to Fides EMS and optimise

your resources - quality guaranteed!